Our Location

Jl. Mastrip No.9A, RT.7/RW.3, Rambutan, Kec. Ciracas, Kota Jakarta Timur, DKI Jakarta

In the world of logistics and warehousing, efficient storage solutions are essential for optimizing operations and maintaining a smooth workflow. Racking system for warehouses is a fundamental component of warehouse infrastructure, enabling businesses to store and manage their inventory effectively. This article explores the various types of racking systems available for warehouses, their benefits, applications, and key factors to consider when implementing these systems.

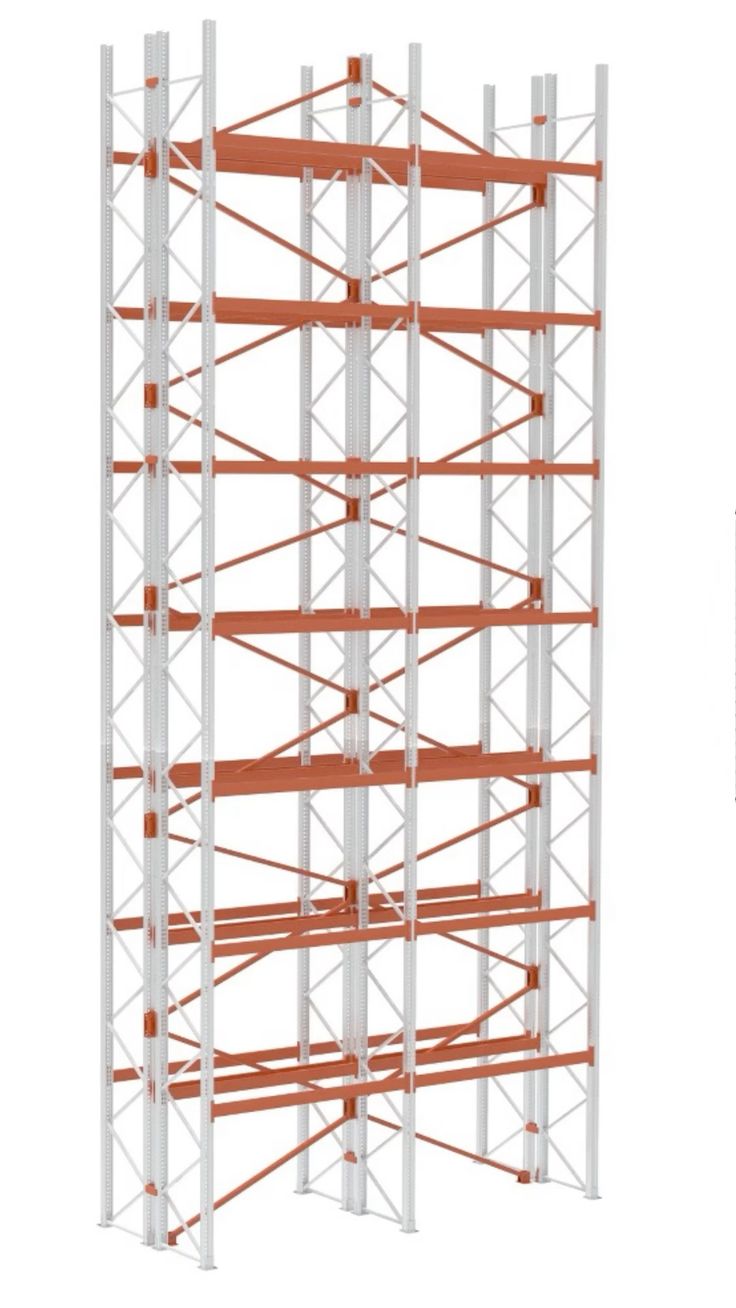

Racking system for warehouses is a storage solution designed to store goods and materials in an organized and accessible manner. These systems consist of various types of racks, shelves, and supports, which can be customized to fit the specific needs of a warehouse. By utilizing vertical and horizontal space efficiently, racking systems help maximize storage capacity, improve inventory management, and enhance overall operational efficiency.

There are several types of Racking system for warehouses, each tailored to different storage needs and warehouse configurations. Here are some of the most common types:

Selective pallet racking is the most widely used racking system due to its versatility and ease of use. It allows for direct access to each pallet, making it ideal for warehouses with a wide variety of products. This system consists of upright frames and horizontal beams, which can be adjusted to accommodate different pallet sizes and weights. The primary advantage of selective pallet racking is its accessibility, ensuring that any item can be retrieved quickly and easily.

Drive-in and drive-through racking systems are designed for high-density storage. These systems minimize the need for aisles by allowing forklifts to drive directly into the rack structure to load and unload pallets. Drive-in racking has only one access point, while drive-through racking has two, allowing for greater flexibility in inventory management. These systems are ideal for storing large quantities of similar items that do not require frequent rotation.

Push back racking systems use a series of nested carts that move along inclined rails. When a new pallet is loaded, it pushes the previous pallets back, and when a pallet is removed, the remaining pallets roll forward. This system allows for high-density storage and better space utilization, as multiple pallets can be stored on each level. Push back racking is well-suited for medium-turnover products.

Pallet flow racking, also known as gravity flow racking, uses gravity to move pallets from the loading end to the picking end on inclined rollers. This system supports a first-in, first-out (FIFO) inventory management approach, making it ideal for perishable goods and items with expiration dates. Pallet flow racking maximizes storage density and ensures efficient product rotation.

Cantilever racking is designed for storing long, bulky items such as pipes, lumber, and sheet materials. It features arms that extend from a central column, allowing for unobstructed storage of items of varying lengths. Cantilever racking systems are highly adaptable and can be adjusted to accommodate different load sizes and weights.

Double-deep racking is a variation of selective racking where pallets are stored two deep instead of one. This system increases storage density by reducing the number of aisles required. However, it limits direct access to pallets, as only the front pallet is immediately accessible. Double-deep racking is suitable for warehouses with lower turnover rates.

Mezzanine racking systems add an additional level of storage above existing racks, effectively doubling the available storage space without expanding the footprint of the facility. These systems are ideal for warehouses with high ceilings and can be equipped with stairs, lifts, and conveyor belts to facilitate easy access to stored items. Mezzanine racking is a cost-effective solution for increasing storage capacity.

Implementing Racking system for warehouses offers numerous benefits that enhance operational efficiency and safety. Here are some key advantages:

Warehouse racking systems are designed to optimize the use of vertical and horizontal space in a facility. By storing items in tall racks and utilizing the full height of the warehouse, businesses can significantly increase their storage capacity without expanding the physical footprint.

These systems facilitate better organization and accessibility of inventory, making it easier to locate and retrieve items quickly. This leads to improved inventory accuracy, reduced handling times, and increased overall productivity.

Warehouse racking systems are built to support substantial weight loads, reducing the risk of rack failure and associated accidents. They are designed with safety features such as load-bearing beams, safety pins, and braces to ensure stability and secure storage.

By maximizing storage space and improving inventory management, warehouse racking systems help reduce operational costs. Businesses can save on space rental or construction costs and minimize labor expenses through more efficient handling and retrieval processes.

These systems are highly customizable and can be adjusted or expanded as storage needs change. This flexibility allows businesses to adapt their storage solutions to accommodate growth and evolving inventory requirements.

Racking system for warehouses are used across a wide range of industries to improve storage efficiency and operational workflows. Here are some examples of how these systems are applied:

In manufacturing facilities, Racking system for warehouses are used to store raw materials, work-in-progress items, and finished goods. These systems ensure that essential materials are readily available for production processes, minimizing downtime and enhancing productivity.

Distribution centers and logistics hubs rely on warehouse racking systems to manage large volumes of goods efficiently. These systems support fast and accurate order fulfillment, helping to meet customer demands and reduce lead times.

Large retail stores and warehouses use warehouse racking systems to organize and store merchandise. This allows for better inventory control, quicker restocking, and improved overall store operations.

The food and beverage industry uses warehouse racking systems to store perishable and non-perishable goods. Systems like pallet flow racking ensure proper stock rotation and easy access to products with expiration dates, maintaining product quality and safety.

In the automotive industry, warehouse racking systems store heavy and bulky items such as engines, transmissions, and body parts. These systems provide safe and efficient storage, ensuring that parts are easily accessible for assembly or repair operations.

Pharmaceutical companies use warehouse racking systems to store raw materials, active ingredients, and finished products. These systems help maintain organization, ensure compliance with regulatory standards, and facilitate efficient inventory management.

Selecting the right Racking system for warehouses for your facility requires careful consideration of several factors. Here are some key considerations to keep in mind:

Consider the size, weight, and shape of the items you need to store. This will determine the type of racking system that best suits your needs. For example, cantilever racking is ideal for long, bulky items, while pallet flow racking is suitable for products with high turnover rates.

Evaluate the available floor and vertical space in your facility. Warehouse racking systems can maximize vertical space, but you need to ensure there is enough clearance for safe operation of material handling equipment such as forklifts.

Ensure that the chosen racking system can support the weight of your inventory. Overloading racks can lead to structural failure and pose significant safety risks. Always adhere to the manufacturer’s load capacity guidelines.

Determine how frequently you need to access your stored items. If quick and direct access is essential, selective pallet racking might be the best option. For items that are not accessed frequently, drive-in or push back racking systems may be more suitable.

Consider the safety features of the racking system, such as load-bearing capacity, stability, and the inclusion of safety pins and braces. Compliance with industry safety standards and regulations is crucial to ensure the well-being of workers and the protection of stored goods.

Choose a racking system that can be easily adjusted or expanded to accommodate future growth. Scalability is important for businesses that anticipate changes in inventory levels or types over time.

To illustrate the benefits and implementation process of Racking system for warehouses, let’s examine a case study of a manufacturing company.

ABC Manufacturing, a producer of heavy machinery components, faced challenges with limited storage space and inefficient inventory management in their warehouse. As production increased, the need for a more efficient storage solution became critical.

ABC Manufacturing implemented a combination of selective pallet racking and cantilever racking systems. Selective pallet racking was used for storing smaller, palletized items, while cantilever racking was installed for long, bulky components such as metal beams and pipes.

Racking system for warehouses are essential for businesses seeking to optimize their storage space, improve inventory management, and enhance operational efficiency. With various types of racking systems available, companies can select solutions tailored to their specific needs, whether for storing heavy machinery parts, perishable goods, or retail merchandise. By considering factors such as inventory type, space availability, load capacity, and safety requirements, businesses can implement the most effective storage solutions to support their growth and operational goals. Warehouse racking systems are not just practical necessities; they are strategic investments in the future success and efficiency of any industrial or commercial operation.

Untuk memesan atau mendapatkan informasi lebih lanjut tentang RACKING SYSTEM FOR WAREHOUSES / rak gudang kapasitas besar untuk warehouse industri, hubungi tim marketing kami di:

Telepon: 021-87786434 / 87786435 / 87786436

WhatsApp: 081288551012 / 081296786785 / 082184497726

Tim kami siap membantu Anda memilih produk yang tepat dan menjawab semua pertanyaan Anda.

Terima kasih,